OCA Bonding

Why do we need to apply for the OCA bonding / dry bonding process?

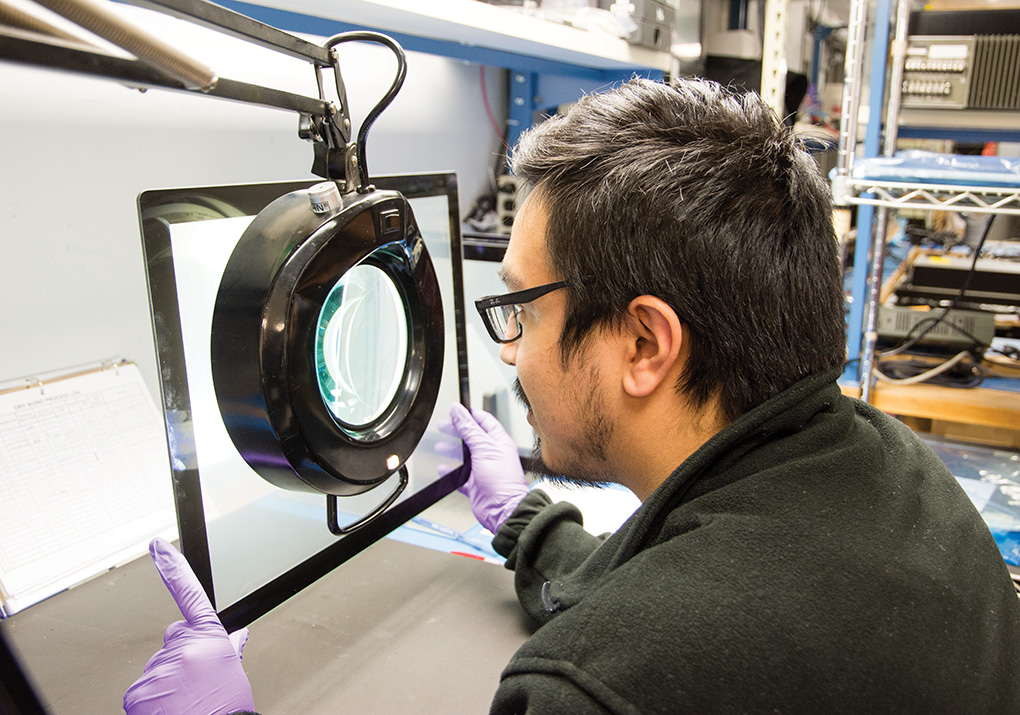

We create a bonding between the glass cover and a lcd screen using a optically clear OCA sheet or LOCA layer. This process is performed in a vacuum chamber and yields void free lamination results. In simple terms, we dry OCA layers to eliminated the air gap between a glass cover and the LCD screen.

In a traditional, Non bonding LCD screen, there is an air gap between glass cover and lcd display, thus the optical clarity is reduced and sunlight reflection is increased. Making it is diffuclit to use in semi outdoor or outdoor enviornments.

What is benifits of OCA bonding ?

- Once the dry bond is applied, the final product is less likely to get foggy, and the bond is stable up to an altitude of 55,000 feet (tested).

- We offer multiple dry bond materials, with different amplitudes, that fit your frequency range needs.

- The finished product exhibits excellent resistance to vibration/shock.

- It is possible to add additional layers of optical substrates to improve resistance to boot-kick or ballistic applications.

- Dry bonding is a more cost effective system to implement than wet-bonding, and yields faster turnaround time.

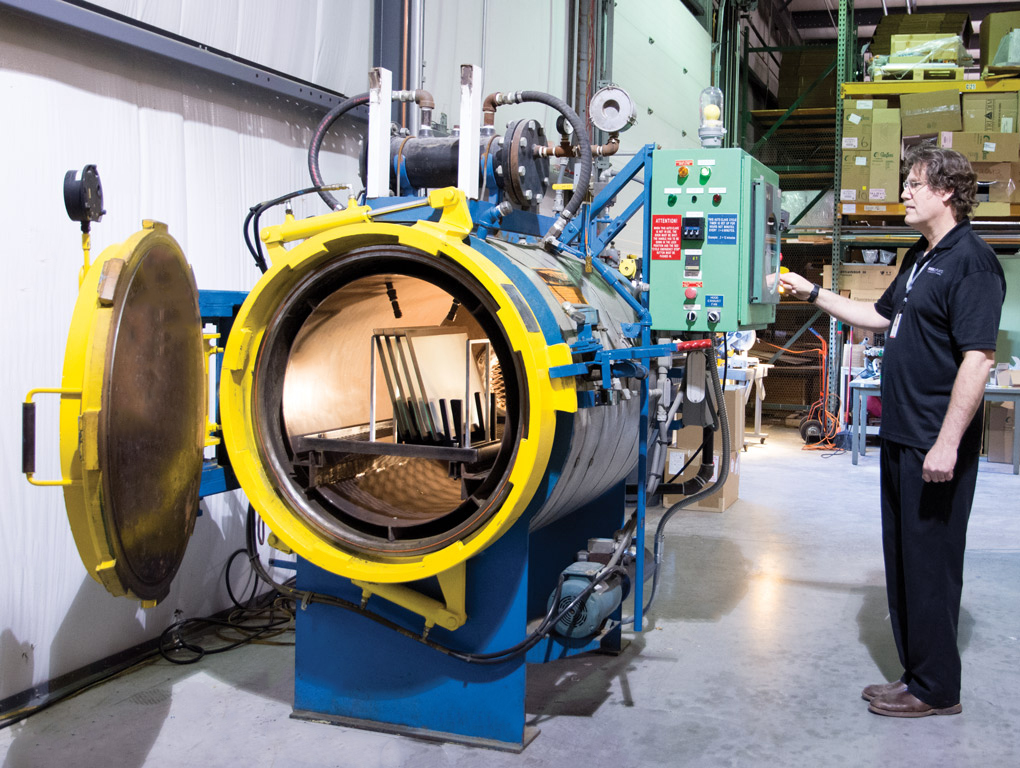

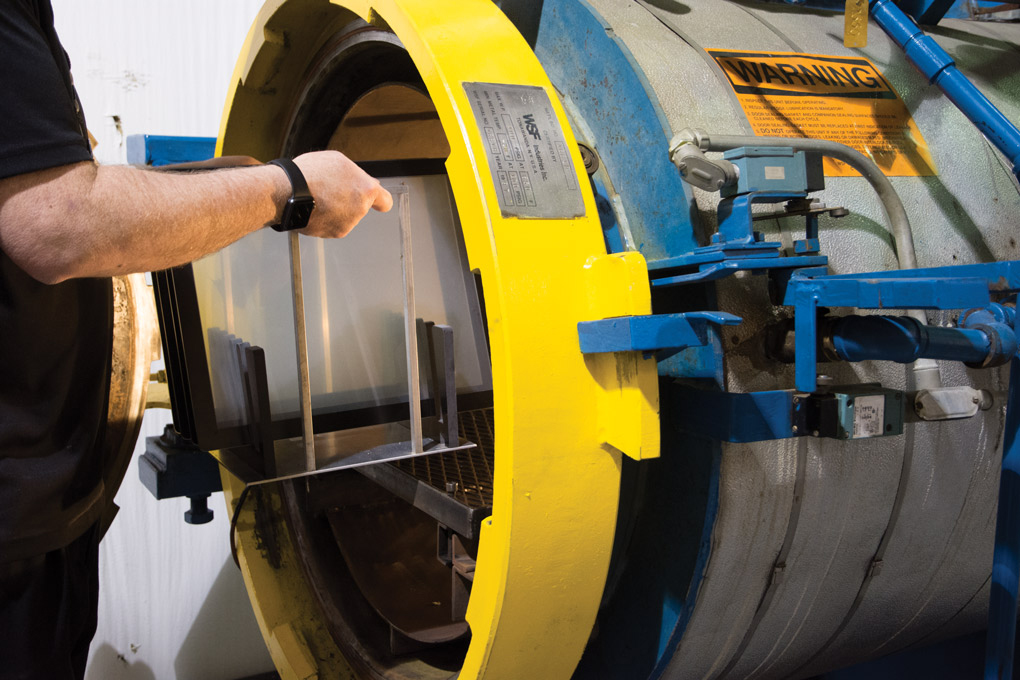

OCA Bonding Process in Photos.

Industrial autoclaving is an advanced process for enhancing lamination. Dry heat and pressure are introduced to the product layers, creating a strong seal. Minute air bubbles that exist in pre-autoclaved layers, are removed via the autoclave process - resulting in a product that performs as intended in extreme conditions.

If the air gaps are not removed, the product’s structural integrity can be weakened causing breakage or deformation of the bonded layers.